Tomorrow’s Tech, Today: Innovation That Moves Us Forward

Forward-looking: In a quiet corner of Beltsville, Maryland, a new chapter in battery technology is unfolding. Ion Storage Systems, a company that began as a university research project, has emerged as a leading contender in the race to commercialize solid-state batteries – a technology long promised but rarely delivered at scale.

After a recent visit to the company’s Maryland facility, The Wall Street Journal concluded that Ion Storage Systems stands out as a company with a real chance of achieving this long-sought breakthrough. Backed by the US Department of Energy and private investors, Ion’s batteries are now rolling off the production line, with early units already being tested by the Department of Defense and major electronics manufacturers.

Solid-state batteries are often described as the holy grail of energy storage. Unlike conventional lithium-ion batteries, which use a liquid electrolyte and a graphite anode, solid-state batteries replace the liquid with a solid ceramic material and often use lithium metal as the anode.

This design promises a host of benefits: higher energy density, faster charging, longer lifespan, and, crucially, greater safety. Traditional lithium-ion cells are prone to overheating and, in rare cases, catching fire. The solid ceramic separator in Ion’s design is nonflammable, dramatically reducing that risk.

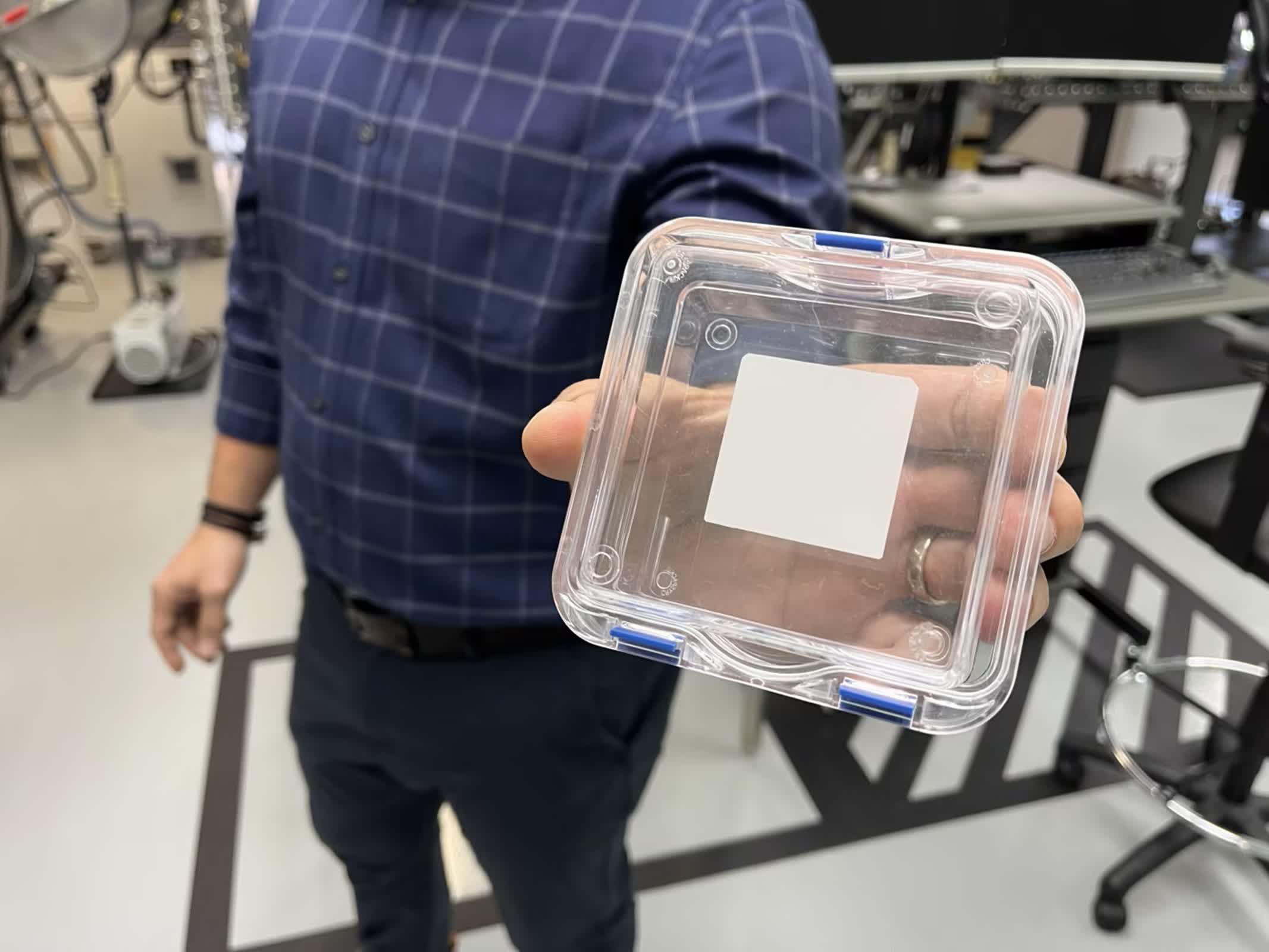

The technical heart of Ion’s innovation lies in its unique ceramic electrolyte. Where most solid-state batteries struggle with expansion and contraction – often called “breathing” – as they charge and discharge, Ion’s three-dimensional ceramic structure acts as both a separator and a buffer. The porous ceramic allows lithium ions to move efficiently between the electrodes while accommodating the physical changes that occur during cycling.

This eliminates the need for heavy compression systems, metal plates, or springs that add bulk and complexity to other solid-state designs. The result is a battery that can be packaged in thin, flexible pouches, much like today’s lithium-ion cells, but with far greater performance and safety.

Manufacturing these batteries is no small feat. The ceramic layer must be produced in meticulously clean environments, using processes more akin to semiconductor fabrication than traditional battery assembly. Ion recently invested in advanced sintering furnaces to expand its ceramic production, positioning itself to scale up from pilot production to commercial volumes. The company’s new 33,000-square-foot facility employs 75 people, with plans to double that number as production ramps up.

Ion’s batteries have already achieved impressive technical milestones. The company’s cells have achieved over 1,000 charge cycles in laboratory tests, retaining more than 80% of their capacity – a key requirement for consumer electronics and electric vehicles. Unlike many solid-state prototypes that require external pressure to maintain contact between layers, Ion’s design is fully compressionless and anodeless, simplifying manufacturing and integration into existing products.

The path to commercialization is notoriously difficult in the battery industry, where many promising technologies fail to scale or meet real-world demands.

The path to commercialization is notoriously difficult in the battery industry, where many promising technologies fail to scale or meet real-world demands. Yet Ion’s approach has attracted significant attention from both government and industry. The company recently secured $20 million from the Department of Energy’s ARPA-E program, matched by private investment, to accelerate development and manufacturing. Collaborations with global materials companies like Saint-Gobain and technology firms such as KLA are helping Ion refine its processes and prepare for broader market entry.

Venture capital investment in solid-state battery startups has declined in recent years due to repeated setbacks across the sector, and while skepticism remains, Ion’s progress is notable. Its batteries are already being evaluated for military applications, where reliability and safety are paramount, and for next-generation consumer electronics, where longer battery life and faster charging are highly valued.

If Ion can continue to meet its technical and manufacturing milestones, the implications are far-reaching. Solid-state batteries could enable electric vehicles with significantly longer range, smartphones that last days on a single charge, and even the electrification of heavy equipment and aircraft.

For the US and its allies, developing this technology domestically is also a strategic priority, offering a chance to reduce reliance on foreign battery suppliers and leapfrog competitors in the global energy transition.

Image credit: The Wall Street Journal

Read the full article on the original site